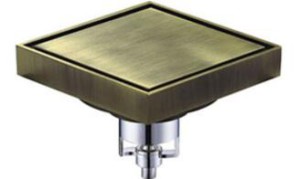

With low carbon steel as the backing, sintered bronze as a medial layer, mixed PTFE with fibers as a self-lubricating layer.

Suitable for dry running with a low coefficient of friction, low wear rate, good sliding characteristics, the transfer film created will protect the mating metal surface.

Suitable for rotary and oscillating movement, high chemical resistance, lower absorption of water, and reduced swelling. Also performs well with lubrication.

( also known as SF-1 or DU)

Application characteristics

1. Suitable for oilless or few grease working conditions;

2. Long maintenance-free; Long operating life due to low friction;

4. low vibration, low noise, and non-pollution in operation;

5. Thin wall thickness & low weight for the machine with compact design;

6. low hardness of mating shaft can be mated, so the shafts processing is easy;

7. PTFE film is transferred to the mating shaft, to protect the mating metal surface, also improve running properties;

8. lower absorption of water, heat dissipation, and reduced swelling, to keep the exact sizes;

9. Cu or Tin plated in outer Surface, for good anit-corrosion.