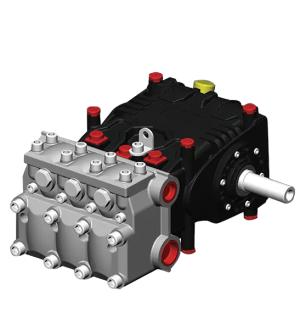

Model: CNC642A Type

Machine Features

CNC642A wire rotating spirng forming machine adopts CNC control system and five sets of servo motors. The cam axis, feeding axis, quill rotary axis, wire rotation axis and auxiliary axis, five axis are interconnected when running. Eight-position working continuously, standard five-axis.(servo spinner and second hook station can be added) It is suitable for making various compression spring, square spring, scoll spring, tower spring, double torsion spring, flat spring and such difficult abnormity springs. Greatly enlarge the spring processing range. The machine has tracking detection, if there is subquality product, the machine will automatically stop.

Model

CNC642A

Wire Diameter(mm)

1.4-4.2

Outside Diameter(mm)

MaxD70

Feeding Length(mm)

0.01-9999.99

Wire Feed Speed

0-70m/min

Can Setting value

0.1~-359.9

Wire Feed Servo Moter

5.5KW

Cam Servo

7Kw

Zaxis Servo

1.5KW

Wire Rotate Servo

3.8KW

Spinner Servo

1 KW

PowerAc

380V10%v50Hz

Dimensions(LxWxH)(mm)

2400x1300x2250

Machine Weight

3200

The feeding system are equipped horizontally at the rotation system of the machine, two rollers as one group. CNC642A has three group feeding rollers.

Different wire size need different feeding rollers. The computer control the feeding system, the moving unit is 0.01mm, the maximum moving length is 99999.99

unit. Adopt the car engine lubricating method inside.

The feature: abrasion-proof, minimum noise, high precision synchronism with the control system.