Traditional certification methodologies impose invisible burdens on modern lighting supply chains. Ip65 Tube Waterproof Fixture manufacturers face critical inefficiencies when managing parallel approval processes for global markets through disconnected workflows. This operational fragmentation creates version control challenges, inventory complications, and quality consistency risks that ultimately compromise project viability.

Conventional compliance approaches contain fundamental contradictions. Most Ip65 Tube Waterproof Fixture operations maintain separate production documentation for different certifications despite significant technical overlaps. Crucially, this duplication prevents knowledge transfer where solutions for one standard could benefit others. These inefficiencies manifest as delayed market entry, unnecessary engineering rework, and compromised production flexibility across global projects.

Innovative manufacturing platforms implement concurrent compliance architecture. Progressive facilities develop products against consolidated requirement matrices during design phases, eliminating certification-specific alterations downstream. Others deploy programmable production endpoints that adapt fixture specifications dynamically without physical line reconfiguration. This maintains standardization while accommodating regional variations efficiently.

Cigelighting redefines agile certification through our GlobalSync Production Ecosystem. Our Ip65 Tube Waterproof Fixture environment enables simultaneous compliance across regulatory regimes within unified workflows. Partners gain real-time adaptation to regulatory updates without manufacturing disruption.

Choose Cigelighting for uncompromised global scalability. Our responsive manufacturing philosophy delivers certified performance without version fragmentation, transforming compliance complexity into competitive advantage.click https://www.cigelighting.com/product/ to reading more information.

• $1.00

Pinned onto shopping

Related Pins

Double-ended writing tools align well with today’s fast-paced creative workflows. Users want to switch between fine detailing and expressive strokes without interrupting their process. A well-designed dual-tip marker reduces clutter while enhancing ef ...

弊店は主にブランド シャネル、ルイヴィトン、グッチ、バーバリー、エルメス、プラダ、MCM、YSL等のiphone 14 15 16 17スマホケース アップルウォッチバンドairpods pro3 4 pro2を営んでいます。スーパーコピーやパロディブランドのGalaxy s26 ultra s25 plus s24 a56 a5 ...

高級ファッションアイテムは、日常のスタイルに一味違ったエレガンスを加えるだけでなく、長く愛用できる耐久性と品質を提供します。フェンディ洗えるマスクやパーカー、

https://www.biumasks.com/brand-fendi-masks

ルイヴィトンキッズ服 ハイブランド、バーバリーtシ ...

最近はキャッシュレス化が進み、スマホだけでお出かけすることも増えましたよね

肩掛けストラップを付けて、バッグのようにスマホを持っていたり、何かと財布より人前で使うことが多いスマホ。会社用と個人用で2台持ちの人も多いのでは?

batacaseはブランド2026新機種iP ...

Appleの2026 iPhone Air 16 Pro 16 17 pro max 16 17 16 plus は、その洗練されたデザインと最先端の機能で注目を集めています。このブログでは、特にブランドパロディルイヴィトングッチSAMSUNG S26 S25 ultra plus s24+スマホケースバーバリールイヴィトンシャネルグッ ...

A Travel Toiletry Storage Cup

https://www.tzchenye.com/product/articles-of-everyday-use-gifts/toiletries/toothbrush-cup/

is an essential accessory for anyone who travels frequently, providing a convenient way to organize and carry personal hygiene it ...

Folding Trolley

The MDF Folding Trolley is built with medium-density fiberboard (MDF), providing a sturdy yet economical platform for transporting items. Measuring 590 × 290 mm, it supports a maximum load of 250 kg, making it suitable for light to me ...

Electro permanent magnetic chucks

https://www.magnetic-lift.com/product/permanent-magnetic-chuck/

are widely used in modern machining and metalworking for holding ferromagnetic workpieces securely. Unlike traditional electromagnetic chucks that rely ...

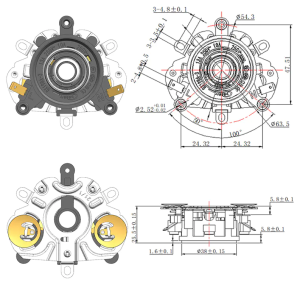

Electric Kettle Coupler

https://www.qianxunele.com/product/kettle-thermostat-coupler/

Rated Voltage:250V

Rated Current:10A/13A

Rated Frequency:50Hz/60Hz

Operating Life:≥10,000 cycles

Contact Resistance:≤50mΩ

Insulation Resistance:≥100MΩ (DC500V ...

Definition and purpose: Stainless Steel Floor Drain Factory

https://www.betterdrain.cn/product/stainless-steel-floor-drains/rw-series/bt-1504-cofloor-drain-with-hinge.html

is a high-quality drainage solution designed for bathrooms, kitchens, balconie ...

Steel Cottage Shed

https://www.sunshinegardencn.com/product/garden-storage-shed/

Size: 6x4FT(W188cm x L125cm x H227cm)

MOQ: 50 sets

Space-Saving Modern Metal-Wood Hybrid Ladder-classroom Row Chair

Upgrade your worship space or modern classroom with our Hot Style Church Seats, a sleek and functional fusion of metal and wood designed for comfort, durability, and space efficiency. P ...

Growing focus on material choice: Stainless steel systems are increasingly preferred for modern buildings due to durability and cleanliness. A professional Stainless Steel Rain Gutter Factory

https://www.szdrainer.com/product/stainless-steel-rain-gutt ...

セリーヌ アディダス iphone 17 ザノースフェイス Galaxy s26スマホカバー

dercase店はブランドのコピースマホケース専売店として、素敵なスマホケース、iphone、google pixel、galaxy、xperia、aquos、apple watch、galaxy watch、airpodsなどの各種機種あり、 ハイブ ...

From the perspective of an Engine Factory

https://www.jnen.cn/product/engine/, safety in wet conditions depends on design standards, protective systems, and correct user behavior.

Focus on flexible materials: Elastic Cutting

https://www.chinajema.com/product/

is specifically designed to process stretchable materials such as elastic bands, tapes, and flexible fabrics, while laser cutting machines rely on heat energy to cut a br ...

ABS Front-Opening Suitcase

The ABS front-opening trolley case launched by Jinwanda Company combines practical design with high-quality materials, bringing many conveniences to users. Its front-opening design is one of the highlights, which is conveni ...

Double Impeller Self-priming Drag Pulley Pump Set

The Double Impeller Self-priming Drag Pump is engineered for high-performance water transfer and irrigation tasks. This 2-inch pump is equipped with a dual impeller system, which significantly enhance ...

Compression Coil Spring Making Machine 6-Axis 3-8mm

Introducing our 6-axis Compression Spring Coiling Machine, an advanced solution for precision spring manufacturing. With a focus on efficiency and accuracy, this machine is designed to meet the dem ...

Antibacterial Deodorant Spray

Antibacterial deodorant spray products play an increasingly important role in modern life. It is not only a cleaning tool, but also a health care product. With its unique functions and advantages, this product has quickl ...

Microwave baking trays

https://www.befairkitchenware.com/product/bakeware/baking-pan/

are exposed to rapid heating, uneven energy distribution, and frequent temperature changes.

Gate Valves of Special Machine Tools for Machining Sealing Surfaces

Special machine tools designed for machining the sealing surfaces of gate valves are essential for industries that rely on the reliable performance of these critical components.

htt ...

Plastic Water Bottle For Adults

https://www.kx-bottle.com/product/

are widely designed for personal hydration, offering large capacities, durability, and advanced sealing mechanisms. These bottles often feature leak-proof lids, flip-top caps, or screw ...

$2,341.17

Grace – 166 cm Elegant Real Love Doll for Adult Companionship

https://www.wifesexdoll.com/real-doll.html

Discover Grace — a beautifully crafted 166 cm real love doll with a slender, graceful silhouette designed to elevate your private experience. With ...

生活にマストなブランドiphone galaxy xpeira google pixelスマホケース ipadケースairpodsケースなど。流行は毎年変化していて、一昨年は「手帳型ケース」、昨年は「斜め掛けショルダー・首掛け・ガラス」など様々な種類があります。

brandidiで2025年おしゃれな実用な ...

The package can also be different printing, materials, and size. OEM and ODM services are available.

The 3-in-1 multi-functional makeup blender is used to apply liquid and powder foundations. All makeup blending sponges are designed with revolutionar ...

Wall Mounted Battery Factory

https://www.paichencn.com/product/home-energy-storage-system/

Product Details Description:

The wall-mounted lithium iron phosphate battery is a household energy storage system that is an ideal choice for solar photovol ...

Plastic Valve Bag Matt Finish Color Printing

The Matt Finish Color-Printing Plastic Valve Bag is an advanced packaging solution for industries requiring high-quality, durable, and visually appealing packaging. This type of bag is widely used for pack ...

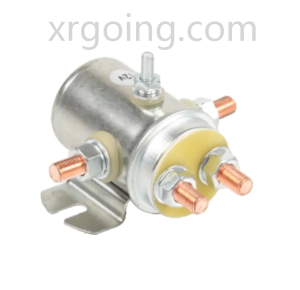

Winch Relay Factory

https://www.xrgoing.com/product/yacht-accessories/winch-relay/

12V/24V

OEM: SW-933 46-2287 440003 24401-01

NAME: Capstan relay

Enamel Casserole Stew Pot Pumpkin Pot Cast Iron

We proudly present our Cast Iron Enamel Casserole Stew Pot, affectionately designed as the Pumpkin Pot. This unique kitchen essential combines timeless craftsmanship with modern functionality, offering ...

Many guidelines from reputable Glass Drill Bit Factory

https://www.zjrctools.com/product/glass-drill-bits/

sources emphasize that understanding material compatibility and operating conditions is the first step in evaluating bit performance. Recognizi ...

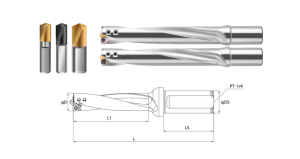

Precise Self-Centering Fast Drill Depth Cutting

HD-3 6D cutting depth precise self-centering fast drill is a cutting tool specially designed for deep hole machining. It is a fast drill suitable for a depth of cut of 6 diameters (6D), thus enabling ef ...

Damping Spring Hinges

https://www.hinges-factory.com/product/

are specialized hardware components designed to provide controlled door closing and opening while reducing noise and impact. They are commonly used in residential, commercial, and industri ...

Classic Steel Door

https://www.zjchenma.com/product/steel-door/classic-steel-door/

Level: 80 Conventional

Size: height 1780~2200, width 860~1080

Panel: frame 1.2 fan 0.6

Hinge: hinge hinge

Door frame: 80 triangular lace frame 130

Lower gear: ...

Pressure Control Factory

https://www.monroswitch.com/product/automatic-pump-control/

The working principle of the device adopts dual control of Pressure and flow. It goes auto on and auto off for the water pump when water pressure changes based on wat ...

SM-361 Spin Mop

Rotary mop is a new type of mop, it overcomes all the shortcomings of the traditional mop, which is portable and easy to clean. Your hands could be completely clean, for it is away from stains and sewage, and it can even affiliate the ...

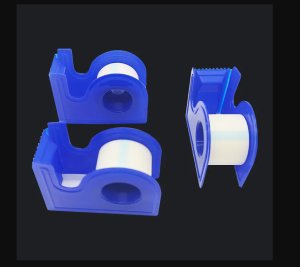

Non-woven tapes are widely used in medical, cosmetic, and industrial applications due to their soft texture, flexibility, and ease of use. One of the important features of non-woven tape is its liquid absorbency, which determines its effectiveness in ...

Graphite Cutting Band Saw Machine

https://www.zjsdsaw.com/product/nonstandard-customization/

is widely used in industries that require precise and efficient cutting of graphite materials. Graphite, being brittle and heat-sensitive, poses unique chall ...

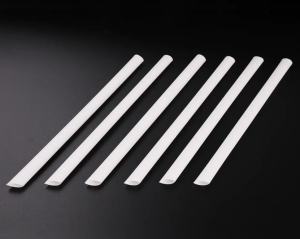

Compostable Straws

We provide compostable straws. It’s made from the Eco-friendly plant-based material-PLA. PLA staws are strong and durable in liquids. It could be in individually wrapped or unwrapped versions.

https://www.shenglinpla.com/pro ...

Luxurious pet sofa LT-6151-4

Dog Couch/ Luxury PU Leather Pet Sofa /with Crystal Button Cat Sofa and Chair /Durable Wooden Frame Dog Couch / Dog Lounge Sofa with Soft Velvet Cushion for Small Dog Using

Item No.LT-6151-4

DescriptionLuxurious pet sof ...

最近はキャッシュレス化が進み、スマホだけでお出かけすることも増えましたよね

肩掛けストラップを付けて、バッグのようにスマホを持っていたり、何かと財布より人前で使うことが多いスマホ。会社用と個人用で2台持ちの人も多いのでは?

batacaseはブランド2026新機種iP ...

生活にマストなブランドiphone galaxy xpeira google pixelスマホケース ipadケースairpodsケースなど。流行は毎年変化していて、一昨年は「手帳型ケース」、昨年は「斜め掛けショルダー・首掛け・ガラス」など様々な種類があります。

fatecaseで2025年おしゃれな実用な ...

Convenient Intelligent energy-saving kerosene stove

Welcome to the future of cooking convenience and sustainability! As manufacturers of cutting-edge Intelligent, Convenient, and Energy-Saving Kerosene Stoves, we are thrilled to present a revolutiona ...

Eyeshadow Container

https://www.zjwlsj.com/product/eye-shadow-palette/

Classification: Eye shadow palette-multiple grids

External size: Ø99*96*17.8mm

Inner size: Ø19.90*19.90mm

Net weight: 79.55g

Material: Transparent layer: AS; cover, inner pl ...

A Water Plowing Aerator

https://www.chinaaerator.net/product/other-aerators/water-plowing-aerator/

is often compared with surface aerators, diffused air systems, jet aerators, and impeller-based solutions. To make an informed decision, it is importan ...

シュプリームギャラクシー s26 ケースceline/chanel子供服激安バーバリー Fendi

Chantip|Galaxy S26 ハイブランドケース × 激安ブランド子供服 ラグジュアリー × トレンド 高コスパで GET✨

スマホにハイブランドのスタイルを添え、お子様の衣装に激安で高クオリティな ...

弊店は主にブランド シャネル、ルイヴィトン、グッチ、バーバリー、エルメス、プラダ、MCM、YSL等のiphone 14 15 16 17スマホケース アップルウォッチバンドairpods pro3 4 pro2を営んでいます。スーパーコピーやパロディブランドのGalaxy s26 ultra s25 plus s24 a56 a5 ...

biumasksはブランド偽物・パロディ・パチモン優良店です。 芸能人愛用のブランド品の本物と偽物見分けがつかないほど精巧に作られています。

ブランド服コピー 激安屋、スーパーコピー服優良店「biumasks」、水沢ダウン 偽物,スーパーコピー tシャツ,大人気パロディtシ ...