Description

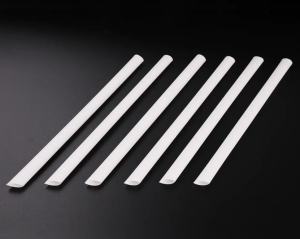

Nowadays, with the development of plastic molds in the direction of high precision and high complexity, many parts that previously required the use of hardware have been replaced by plastic parts. This can increase production efficiency and reduce production costs. The use of Car Door Speaker Cover Frame Mould to produce automotive interior speaker covers is a typical example.

The car interior speaker cover is mainly used to make the sound of the speaker pass through the mesh, and it is also dustproof and beautiful. The speaker mesh on the surface of the horn cover is required to be small and uniform, and the reflection at all angles must be consistent. Due to its high surface quality requirements, it has always been a difficult point to directly form the speaker mesh with the Car Door Speaker Cover Frame Mould.

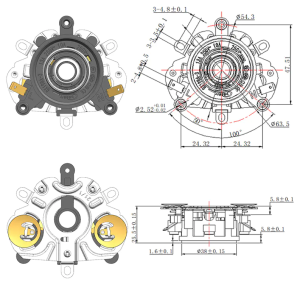

Parameter

Car Door Speaker Cover Frame Mould

Core/Cavity Steel

2738

Mould Base

LKM

Mould size

900*700*550

Cavity

2+2

Injection System

Hot Runner

Runner

Yudo/DME/HUSkY

Mould Life

1,000,000 shots

Plastic material

PP

Design Software

NX Siemens, PROE, Cimatron, Solidwork,Catia and Auto-CAD

Delivery Time

65 days

Payment

By T/T

Advantages

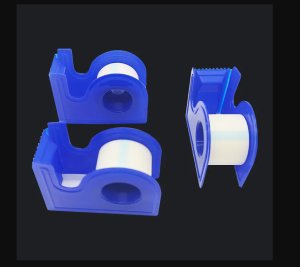

Car Door Speaker Cover Frame Mould has 3M self-adhesive tape on the back.

The surface must be clean and dry before adhering.

It is used to decorate the car’s exterior and make your car special and unique.

It is easy to install and requires simple stripping and pasting without any modifications.

Hot Tags: car door speaker cover frame mould, China, suppliers, manufacturers, factory, customized, low price, Plastic Injection Jug Mould, Interior Car Door Panels Mold, Auto Front Head Lamp Mould, Car Door Armrest Mould, Car Door Map Pocket Mold, Injection Plastic Chair Mould