Best Quick 861DW Hot Air Gun Rework Station – OEM New – REWA

Related Pins

$1

12 Antenne 3G/4G LTE/GPS LOJACK Blocker UHF/VHF Signal störsender

https://signalstorer.com/products/12-antenne-3g-4g-lte-gps-lojack-blocker-uhf-vhf-signal-storsender

$1

https://signalstorer.com/products/der-neueste-tragbare-storsender-mit-16-antennen-fur-handysignale

Die neuesten tragbaren drahtlosen 5G-Signalstörsender mit All-in-One-Design, die 2G-, 3G-, 4G-, 5G- und CDMA-450-MHz-16-Frequenzbänder, alle Arten von ...

Product Feature XSE-10S-ultra high pressure solenoid valve for gas,liquid,light oil

•Suitable medium: Liquid、gas、light oil( Vicosity<20Cst)

•Ambient temperature: -10°C- 50°C

•Working voltage:AC220V/110V 50/60Hz DC24V IP65 H insulation, other v ...

■Product features of XSD-15S-Normally Open water solenoid valve.

•Suitable medium:liquid,water,hot water,gas

•Medium temp.: -10℃- 8℃

•Action type: pilot operated type

•Working status: normally closed / normally open

•Valve body material: brass(fo ...

![Product advantages of positive display LCD speedometer:

[1] high-quality material, exquisite and ...](http://ie-colle.com/wp/wp-content/uploads/2021/11/offroaderwithliner-1636535470cp4l8-300x300.jpg)

Product advantages of positive display LCD speedometer:

[1] high-quality material, exquisite and smooth,

[2]Safety and environmental protection

[3] Full LCD display, even if driving at night, all situations are clearly visible

[4] The product has good ...

In recent years, double color mould has become more and more popular, and bi color mould looks more beautiful and popular. Buy two color mould and choose Huangyan shine mould, we are experts in this field, equipped with an experienced design and manuf ...

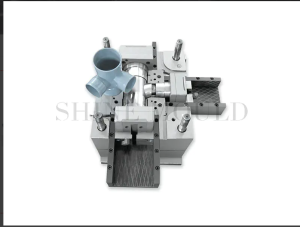

Information Pipe Fitting Mould:

Product Details

Product: Plastic Mold MoldNO: Customized

Brand: SHINE Color: Customized

Placeof Orngin: Huangyan,China Size: Customized

Material: Plastic Packing: Poly Wood Box

Advantage: OEM Is Available Shaping ...

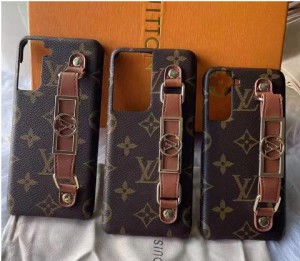

ブランド ルイヴィトンiphone13proケースモノグラムシャネル iphone13pro maxケース 手帳型

今、スマホケースはファッションのアイテムになりました。弊店には憧れのグッチXperia 1 III/10 IIIケースブランド、グッチ、シャネル、エルメス、シュプリームなどのブランドス ...

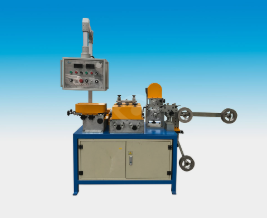

This type equipment can produce all kinds SPEC injector.include middle head direet insert type & two piece set injector may design&produce.Adopt all computer touch screen control.no injection silicon oil & plugging needlecan inspect.defici ...

グッチ galaxy s21+/s21ultraケース Gucci ハイブランド

皆さん、こんにちは!最近スマホケースはますますファッションのアイテムの1つになりましたね。皆さんはどのブランドが好きですか。今日ぐっちとルイヴィトンのGalaxy s21/s21ultra /s20+ケースをご紹介いたしま ...

Information of automatic syringe assembly machine:

1. Control system adopts computer touch screen

2. The shield of machine is all made stainless steel material

3. Speed control system adopts Japan’s mitsubishi inverter

4. enjoy testing product ...

This equipment can be continuous spaced printing, chain transmission, double circulation wind electric heating drying, equipped with cam segmentation, product stable transmission, precise positioning. The shell of the quipment is made of stainless ste ...

Information of this kind of mould:

Mould Life:3,000,000 shots

Mould Cavities:Multiple Cavities,can be customized

Runner Type:Cold runner,Semi Hot Runner

Mould Steel:Core and cavities:S136/Cr12/DC53

Base:60#/5GrNiMo/4Cr13

(the Mould steel can be ...

This machine is used for printing syringe barrel. It has the characteristics of high working efficiency, low power consumption, low cost,simple regulation, high qualified rate and wide use and adoption of 1.5kw Speed regulating motor. The production e ...

This equipment can be continuous spaced printing, chain transmission, double circulation wind electric heating drying, equipped with cam segmentation, product stable transmission, precise positioning. The shell of the quipment is made of stainless ste ...

$0.00

Buy Cheap RuneScape Gold(OSRS/RS3) For Sale. More Runescape products in https://www.winrsgold.com

Rubber hose production line because penetrate the rubber and heat the material from core to rubber hose production line.

Rubber extruder machine are mainly aimed at rubber extruder machine.The decibel level created with our rubber extruder machine is much less versus other alternatives.

The epdm extruder comes with an anti-wear coated barrel-and-screw combination, a rubber extruder and can be set and monitored via an integrated control system in the extruder.

The rubber extruder machine solves the most critical issues manufacturers face to deliver tough.The testing instrument is also known by the name thermostat that controls the temperature of the chamber efficiently.

We have been able to design and develop a sustainable range of rubber extruder.The inner parts of these rubber extruder are made utilizing good quality stainless steel.

In addition, we also offer product customization as per our valued clients’ epdm extruder.Wear resistance and other characteristics that will impact the performance of the epdm extruder.The epdm extruder can be used primarily for the production ...

Robust design.Easy to operate.Less power consumption.This process makes the salt bath curing line, more durable, and more resistant to extremes in temperature.Microwave curing oven also provided a shorter cure time and an equivalent degree of conversion.

rubber extruder is a kind of basic equipment in rubber industry.Rubber generally conforms to possible deterioration due to many reasons.As rubber extruder, in rubber extrusion process the rubber is forced through a die of the desired cross-section und ...

The rubber extruder process begins with a rubber compound being fed into an extruder.Rubber is a naturally occurring elastomer, cultivated from the Pará Rubber Tree.A heated shearing screw conveyor and a die in which the pressurised rubber is squeezed ...

The rubber extruder for these composite materials frequently includes bagging and putting them under a vacuum while being cured.These ovens are used to cure these coatings or other materials onto the parts.

Every project has unique needs and requires different material properties for custom rubber molded products.It is highly accurate and maintains tight tolerances,rubber extruder, on-time and within specifications.

microwave curing oven are less sticky and have superior mechanical properties.Vulcanization is process of converting natural rubber or rubber polymers into more durable and mechanically strengthens rubber by the process of mixing sulfur and processing.

Plastics, rubber extruder and even food use the extrusion process. rubber extruder consist of a heated shearing screw conveyor or twin screw conveyor and a die through which the plasticised and pressurized rubber is squeezed.

rubber hose production line is the way of transforming natural rubber and comparable versatile polymers into durable products by cross.These rubber hose production line can be custom designed to accommodate curing applications for materials such as pl ...

Moist heat sterilization uses water to boil items or steam them to sterilize and doesn’t take as long as dry heat sterilization.The rubber extruders can be used primarily for the production of profiles of much differentiated shapes.Over the year ...

rubber hose production line are used for a variety of applications involving coatings, adhesives, rubber and thermoset plastics and composites.From start up to your operating temperature only takes a few minutes eliminating long start up times.

Once the material reaches the die, the built-up pressure forces the material through the openings, where it will consequently swell to various degrees based on the material compound and hardness.The rubber extrusion process begins with a rubber compou ...

Unlike other methods, the rubber extruder lends itself well to high volume lineal foot production runs.Rubber processing extruders that operate by cold feeding of strips are used in rubber extruder for a diversified range of applications like tire com ...

Its product range comprises the microwave curing oven, the test laboratory with various test stations as well as the cleaning and recycling equipment for the bandage and the plastic mandrels.The function of the microwave curing oven is to utilize high ...

The number of sulfur atoms in the crosslink strongly determines the physical properties of the final rubber article. Short cross-links give the rubber better heat resistance.A vast array of products is made with vulcanized rubber including tires, auto ...

Rubber extruder is a chemical process for converting rubber or related polymers into more durable materials through.Our rubber extruder offer continuous temperature up to 250°C and feature safe operation.There are various optional accessories that our ...

microwave curing oven is seen as a solution to shorten the semi-curing process.Microwave Heating has been proven to be equally suited for Sponge, Solid and Co-extruded profiles.Microwave is used for the process of rubber vulcanization.

The microwave curing oven has such features like advanced design, compact structure, fast mold close/open and high automatization.The machines used for microwave curing oven.

$129.00

Sexy V-neck Red Split Prom Dresses,Simple Slit Sexy Party Dresses PFP0001

$12100

Flat Screen Printing Machine LiCheng