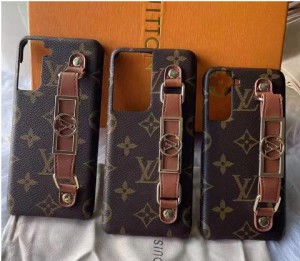

ロエベアイホン13Pro携帯ケース手首ストラップ付きロエベ アイホン13プロマックス 光沢感 スマホケースロエベ iPhone 12 Pro 保護ケース シリコン アイフォーン11promax女性力満点カバー

https://www.buyzaka.com/goods/loewe-iphone12pro-case-1632.html

12 Antenne 3G/4G LTE/GPS LOJACK Blocker UHF/VHF Signal störsender

https://signalstorer.com/products/12-antenne-3g-4g-lte-gps-lojack-blocker-uhf-vhf-signal-storsender

アイホン13 pro/13pro max ロエベ スマホケース 全面保護 手首ストラップ付き アイフォン 12 pro max/12pro Loewe カバー 売れ筋 アイフォーン11promax/11pro/11 スマホケース ロエベ 金属ロゴ付き アイフォーンxr Loewe スマホケース

https://www.buyzaka.com/goods/lo ...

半透明アイフォーン12pro maxカバー アイフォーン12/12mini3色ケース Adidas 携帯ケース ソフト アイフォン 11pro max iphonexr ブランド字母プリント ケース Nike adidasケースクローバー柄アイフォーンxsmax

https://www.buyzaka.com/goods/adidas-iphone12-xs-case-1 ...

https://signalstorer.com/products/der-neueste-tragbare-storsender-mit-16-antennen-fur-handysignale

Die neuesten tragbaren drahtlosen 5G-Signalstörsender mit All-in-One-Design, die 2G-, 3G-, 4G-, 5G- und CDMA-450-MHz-16-Frequenzbänder, alle Arten von ...

Adidas iphone13 スマホケース アディダス iphone12mini 売れ筋 携帯ケース iPhone 12 pro max クローバー柄 携帯ケース Adidas iphone11/11 pro/11 pro max保護ケース流行りAdidas iPhone xr Adidas 送料無料 カバー アイフォン xs max adidas スマホケース ブランド

h ...

Loewe iphone13Pro携帯ケース全面保護 iphone12mini 欧米風 カバー アイフォーン12 pro max 保護ケース ロエベ 携帯ケース アイフォーン11/11pro/11promax 流行り シリコン 保護ケース Loewe アイフォーンxsmax Loewe 携帯ケース アイフォン 8/8 plus

https://www.buyza ...

ブランド ロゴ付き 高品質 キッチン 直径150cm Versace カーペット 円形 宮廷風 ベッドルーム 柔らかい 滑り止め素材 ベッドサイドラグ 子供部屋 滑り止めシート 吸水 フランネル 売れ筋 洗濯機洗い可能 滑り止め 抽象的 海外販売

https://www.buyzaka.com/goods/vers ...

直径150cm fendi ベッドルーム ロゴ付き 純色 ベビーマット フランネル 子供部屋 海外販売 カーペットフェンディ 滑り止め素材 キッチン 滑り止め 宮廷風 高品質 吸水 滑り止めシート 洗濯機洗い可能 文字 ハイブランド 柔らかい送料無料

https://www.buyzaka.com/good ...

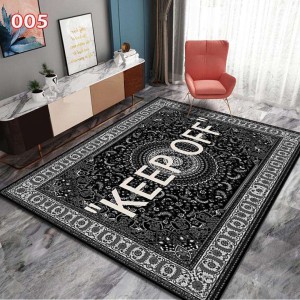

オシャレSupreme カーペット滑り止め 吸水 高品質 フランネル カウズ ロゴ付き 滑り止め素材 ベッドルーム アニメ 欧米風 文字 送料無料 ブランド 売れ筋 キッチン 洗濯機洗い可能 ファッションブランド スポンジ

https://www.buyzaka.com/goods/balenciaga-rug-741.ht ...

滑り止め素材 送料無料 キッチン ハイブランド 流行り フランネル ロゴ付き ベッドルーム カーペット Gucci 洗濯機洗い可能 グッチ 欧米風 オシャレ スポンジ 文字 吸水 滑り止め 純色

https://www.buyzaka.com/goods/gg-rug-717.html

顧客様の支持に応じて、よりよいサ ...

150*200cm 滑り止めシート 吸水 カーペット lv 色移り防止 lv 欧米風 ブランド 滑り止め素材 キッチン 売れ筋 ベッドサイドラグ 柔らかい ベッドルーム フランネル 洗濯機洗い可能 滑り止め 高品質 純色 海外販売

https://www.buyzaka.com/goods/vuitton-rug-1253.html

...

送料無料 滑り止め ロゴ付き 文字 ベッドルーム アニメ 売れ筋 フランネル Kaws ハイブランド 欧米風 高品質 吸水 ファッションブランド 絨毯Kaws洗濯機洗い可能 人気 キッチン スポンジ 滑り止め素材

https://www.buyzaka.com/goods/supreme-rug-723.html

顧客様の支 ...

キッチン ディオール 駿馬 吸水 高品質 送料無料 滑り止め素材 滑り止め ベッドルーム 欧米風 フランネル 絨毯ディオール 文字 洗濯機洗い可能 ブランド ロゴ付き 売れ筋 スポンジ オシャレ

https://www.buyzaka.com/goods/dior-rug-728.html

顧客様の支持に応じて、よ ...

滑り止め素材 アニメ スポンジ ファッションブランド 文字 洗濯機洗い可能 売れ筋 滑り止め ベッドルーム 安い キッチン 送料無料 LV カーペットシャネル ロゴ付き 欧米風 フランネル 高品質 ブランド 吸水

https://www.buyzaka.com/goods/chanel-rug-738.html

Product Feature XSE-10S-ultra high pressure solenoid valve for gas,liquid,light oil

•Suitable medium: Liquid、gas、light oil( Vicosity<20Cst)

•Ambient temperature: -10°C- 50°C

•Working voltage:AC220V/110V 50/60Hz DC24V IP65 H insulation, other v ...

■Product features of XSD-15S-Normally Open water solenoid valve.

•Suitable medium:liquid,water,hot water,gas

•Medium temp.: -10℃- 8℃

•Action type: pilot operated type

•Working status: normally closed / normally open

•Valve body material: brass(fo ...

Product advantages of positive display LCD speedometer:

[1] high-quality material, exquisite and smooth,

[2]Safety and environmental protection

[3] Full LCD display, even if driving at night, all situations are clearly visible

[4] The product has good ...

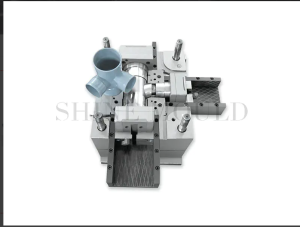

In recent years, double color mould has become more and more popular, and bi color mould looks more beautiful and popular. Buy two color mould and choose Huangyan shine mould, we are experts in this field, equipped with an experienced design and manuf ...

Information Pipe Fitting Mould:

Product Details

Product: Plastic Mold MoldNO: Customized

Brand: SHINE Color: Customized

Placeof Orngin: Huangyan,China Size: Customized

Material: Plastic Packing: Poly Wood Box

Advantage: OEM Is Available Shaping ...

人気 オシャレ ファッションブランド lv 送料無料 男女兼用 人工皮革 流行り 適当な厚さ 穴留め式 欧米風 アップルウォッチバンドルイヴィトン ロゴ付き ブランド

https://www.buyzaka.com/goods/lv-belt-746.html

洗濯機洗い可能 流行り 花卉 ロゴ付き スポンジ 絨毯 シャネル 欧米風 キッチン 滑り止め 高品質 フランネル 文字 送料無料 売れ筋 ベッドルーム 吸水 滑り止め素材 ハイブランド シャネル https://www.buyzaka.com/goods/chanel-rug-751.html

オシャレ カジュアル ソファブランケット ディオール 高品質 フランネル 洗濯機洗い可能 dior エアコンブランケット 売れ筋 文字 車用ブランケット 四季通用 ハイブランド ロゴ付き https://www.buyzaka.com/goods/dior-rug-1007.html

多機能ブランケット ラグジュアリー 送料無料 四季通用 高級感 エアコンブランケット lv毛布 コットン 文字 ディオール ロゴ付き オシャレ ブランド 洗濯機洗い可能

https://www.buyzaka.com/goods/louis-vuitton-rug-1018.html

オシャレSupreme カーペット滑り止め 吸水 高品質 フランネル カウズ ロゴ付き 滑り止め素材 ベッドルーム アニメ 欧米風 文字 送料無料 ブランド 売れ筋 キッチン 洗濯機洗い可能 ファッションブランド スポンジ

https://www.buyzaka.com/goods/balenciaga-rug-741.html

アニメ アディダス 絨毯 オシャレ 流行り ロゴ付き 文字 送料無料 スポンジ オフホワイト ハイブランド キッチン 洗濯機洗い可能 ファッションブランド ベッドルーム 欧米風 吸水 滑り止め素材 滑り止め フランネル

https://www.buyzaka.com/goods/aape-rug-726.html

スポンジ ロゴ付き 文字 洗濯機洗い可能 安い ルイビトン カーペットシュプリーム 滑り止め 滑り止め素材 ベッドルーム 送料無料 ハイブランド キッチン フランネル アニメ 高品質 売れ筋 吸水 欧米風 ファッションブランド

https://www.buyzaka.com/goods/chanel-rug-7 ...

スポンジ 純色 滑り止め素材 キッチン オシャレ 洗濯機洗い可能 送料無料 ハイブランド フランネル ロゴ付き 滑り止め 絨毯 Gucci ベッドルーム 欧米風 吸水 流行り Gucci 文字

https://www.buyzaka.com/goods/gg-rug-717.html

ヴェルサーチ ロゴ付き versace絨毯 柔らかい 洗濯機洗い可能 書斎 高品質 おしゃれ 抽象的 ハイブランド ベッドルーム ラグジュアリー 室内 海外販売 純色 フランネル 吸水 滑り止め 売れ筋

https://www.buyzaka.com/goods/versace-rug-879.html

吸水 送料無料 エルメス 洗濯機洗い可能 ハイブランド スポンジ キッチン 文字 ベッドルーム ディオール カーペット オシャレ ロゴ付き 滑り止め 高品質 滑り止め素材 売れ筋 欧米風 駿馬 フランネル

https://www.buyzaka.com/goods/dior-rug-728.html

ソファブランケット 四季通用 カジュアル 洗濯機洗い可能 ロゴ付き フランネル ディオール エアコンブランケット 高品質 売れ筋 オシャレ ブランド 文字 dior 車用ブランケット

https://www.buyzaka.com/goods/dior-rug-1007.html

ベッドルーム 四季通用 おしゃれ カジュアル hermes毛布 文字 駿馬 コットン 海外販売 burberry 流行り ブランド ロゴ付き 洗濯機洗い可能 綺麗

https://www.buyzaka.com/goods/burberry-rug-1019.html

ゴージャス 送料無料 四季通用 洗濯機洗い可能 車用ブランケット ロゴ付き vuittonエアコンブランケット おしゃれ 純色 ルイヴィトン ソファブランケット フランネル ブランド 大人気

https://www.buyzaka.com/goods/louis-vuitton-rug-1017.html

ブランド ソファブランケット ロゴ付き フランネル 四季通用 アニメ 柔らかい 車用ブランケット 高品質 オシャレ アニメ風 洗濯機洗い可能 GGエアコンブランケット 可愛い グッチ

https://www.buyzaka.com/goods/gg-rug-1009.html

オシャレ 送料無料 ロゴ付き 四季通用 文字 高級感 洗濯機洗い可能 ハイブランド vuitton 多機能ブランケット 綿 エアコンブランケット vuitton毛布 ラグジュアリー

https://www.buyzaka.com/goods/louis-vuitton-rug-1018.html

ブランド ルイヴィトンiphone13proケースモノグラムシャネル iphone13pro maxケース 手帳型

今、スマホケースはファッションのアイテムになりました。弊店には憧れのグッチXperia 1 III/10 IIIケースブランド、グッチ、シャネル、エルメス、シュプリームなどのブランドス ...

This type equipment can produce all kinds SPEC injector.include middle head direet insert type & two piece set injector may design&produce.Adopt all computer touch screen control.no injection silicon oil & plugging needlecan inspect.defici ...

Adidas luxury sport brand iphone13 pro max case the north face

We make the most beautiful yet protective phone cases and tech accessories, made with love in Lexington USA. Free Shipping For All Order with no minimum quantity.

Adidas Case for iPhone ...

送料無料 洗濯可 字母 ブランド風 綿 2021春夏新作 ルイビトン ハイブランド 綺麗 L ロゴ付き 四季通用 寝具セットlv 欧米風

https://www.buyzaka.com/goods/lv-bed-set-200.html

シャネル帽子キャップ ブランド アイフォン13携帯ケース

新品販売のブランドケース モノグラム インスタ風 芸能人愛用、手帳型、ジャケット型、バッグ型、財布型、女性向け、男性向け、鏡付き、シリコン製、手首ベルト付きなど好評販売中、送料無料。

バッグ型 iPhone 13 ...

高品質 ハイエンドカスタム hermes 送料無料 純色 柔らかい 絨毯Hermes 書斎 滑り止めシート 洗濯機洗い可能 ベッドルーム 滑り止め ラグジュアリー フランネル ロゴ付き 吸水 150*200cm ハイブランド 駿馬

https://www.buyzaka.com/goods/hermes-rug-921.html

ラグジュ ...

書斎 抽象的 おしゃれ 室内 売れ筋 ベッドルーム versace ラグジュアリー 海外販売 ロゴ付き 純色 柔らかい ブランド ヴェルサーチ 絨毯 吸水 洗濯機洗い可能 高品質 フランネル 滑り止め

https://www.buyzaka.com/goods/versace-rug-879.html

ベッドルーム Versace おしゃれ 欧米風 アニメ 滑り止め素材 売れ筋 ロゴ付き キッチン 送料無料 ヴェルサーチ カーペット フランネル 文字 洗濯機洗い可能 ブランド スポンジ 綺麗 吸水 滑り止め

https://www.buyzaka.com/goods/versace-rug-750.html

滑り止め素材 送料無料 流行り フランネル 売れ筋 スポンジ 絨毯クロームハーツ キッチン 文字 ハイブランド Givenchy 欧米風 吸水 幾何学模様 ファッションブランド 滑り止め 洗濯機洗い可能 ベッドルーム ロゴ付き

https://www.buyzaka.com/goods/chrome-hearts-rug-7 ...

キッチン 吸水 フランネル ファッションブランド スポンジ 滑り止め素材 絨毯 エイプ 洗濯機洗い可能 欧米風 ハイブランド オシャレ アニメ YSL ベッドルーム 流行り ロゴ付き 送料無料 滑り止め 文字

https://www.buyzaka.com/goods/aape-rug-726.html

洗濯機洗い可能 kaws 滑り止め素材 ハイブランド 文字 人気 吸水 ロゴ付き ファッションブランド ベッドルーム フランネル 送料無料 高品質 欧米風 アニメ kawsカーペット 滑り止め スポンジ キッチン 売れ筋

https://www.buyzaka.com/goods/supreme-rug-723.html

吸水 絨毯Moschino ロゴ付き ハイブランド 滑り止め素材 ファッションブランド 欧米風 スポンジ 送料無料 オシャレ フランネル 洗濯機洗い可能 キッチン 高品質 売れ筋 supreme 文字 ベッドルーム 滑り止め アニメ

https://www.buyzaka.com/goods/balenciaga-rug-741.html

送料無料 ロゴ付き 滑り止め 洗濯機洗い可能 文字 吸水 駿馬 フランネル オシャレ Burberry 絨毯dior ブランド スポンジ キッチン 売れ筋 滑り止め素材 高品質 ベッドルーム 欧米風

https://www.buyzaka.com/goods/dior-rug-728.html

滑り止め素材 キッチン スポンジ 欧米風 大人気 ブランド 絨毯lv ベッドルーム フランネル ロゴ付き ビトン 送料無料 文字 洗濯機洗い可能 滑り止め 吸水 純色 売れ筋

https://www.buyzaka.com/goods/louis-vuitton-rug-748.html

滑り止め素材 送料無料 キッチン ハイブランド 流行り フランネル ロゴ付き ベッドルーム カーペット Gucci 洗濯機洗い可能 グッチ 欧米風 オシャレ スポンジ 文字 吸水 滑り止め 純色

https://www.buyzaka.com/goods/gg-rug-717.html

![Product advantages of positive display LCD speedometer:

[1] high-quality material, exquisite and ...](http://ie-colle.com/wp/wp-content/uploads/2021/11/offroaderwithliner-1636535470cp4l8-300x300.jpg)